Partner of choice

For more than 2 decades, esmo has been at the forefront of the automation market. We have been chosen as a partner by many companies and major brands across different industries such as consumer technologies, automotive, medical engineering, warehouse logistics, and pharmaceutical.

Finding Success with our Solutions

Our state-of-the-art solutions and products enable companies to adapt to ever-changing demands, paving the way towards long-standing relationships and repeat projects.

Customised Testing Equipment for Axial Bearings

The requirements

Automate testing processes for axial bearings

Our customer

A renowned, long-standing expert in fireblanking technology, the company specialises in chipless metal processing. Its global customer base includes large industrial enterprises in the automotive, aviation, medical and optical equipment, and electronic devices industries.

Our solutions

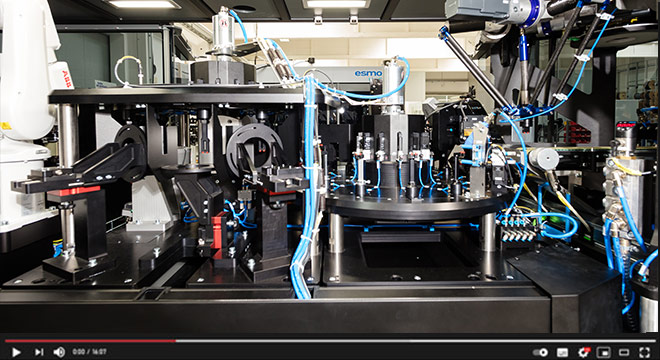

A customised stand-alone automation cell that significantly increased the company’s high repeatability and optimum precision rates.

Features include:

- Inspection of both sides (of bearing discs) for surface defects;

- Performing loading and unloading via magazines (output) and special holders (input);

Loading/ unloading robots, a linear transport system, and inspection cameras.

Assembly Machines and Testing Equipment for Parking Sensors

The requirements

Automate assembly line of vehicle reversing sensors

Our customer

A listed French automotive supplier that specialises in the development, manufacturing, and sale of components, integrated systems, and modules for passenger cars and commercial vehicles.

Our solutions

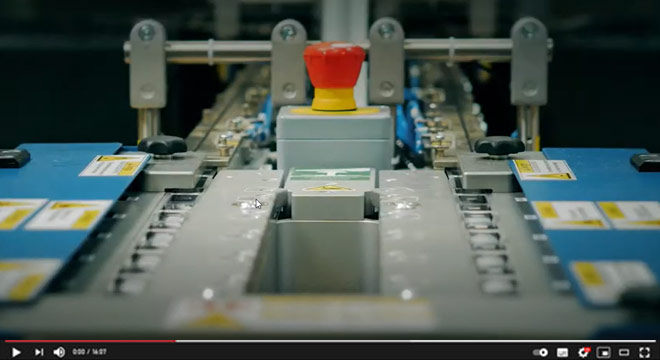

Three assembly and test machines that increased the cycle time per sensor to between 3.5 – 4.2 seconds.

Features include:

- A control platform that connects all modules to the machines;

- Seven camera systems that are used to carry out optical inspection and error detection tests;

2 SCARA robots, a freely programmable ring indexing table, and 2 portal systems.

Width Measurement for Printing Systems

The requirements

Determine the web width of décor paper sheets across various printing press types and alert the operator to abnormalities.

The customer

A world-renowned manufacturer of high-quality printed décor papers. These printed products are used to develop laminates inspired by the natural properties of wood and stone.

Our solutions

We designed and installed 180 width measurement systems that determine the width of each laminate sheet and alert operators to abnormalities, allowing them to correct the manufacturing processes as needed.

Features include:

- Modular system that allows operators to set it to different width specifications and with various printing systems.

Handling of Deep Drawing Plastic Parts

The requirements

Separate and prepare deep drawing plastic parts for filling

Our solutions

A customised automation machine that works within the tolerances of plastic parts and the customer’s cycle time.

Features include:

- 2 vibratory feeders that separate the deep drawing plastic parts;

- 6-axis robot that picks up and feeds the separated parts to the filling line.

Handling of Injection-Moulded Parts

The requirement

Process injection-moulded parts, including demoulding, quality checks, and packing.

Our solution

A customised stand-alone automated machine.

Features include:

- A gantry robot system that picks up the injection-moulded parts from the moulds and then feeds it to the plant via a chain conveyor system;

- Complex camera system with 12 lenses to inspect the components three at a time, on all sides;

- 2 high-speed SCARA robots working at a rate of ~0.33 seconds per part;

- Integrated stacking unit.

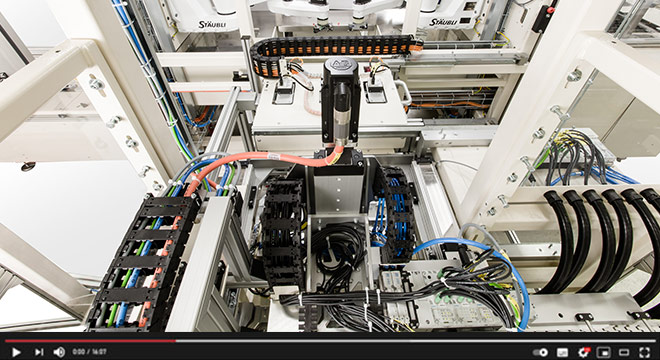

The Trade Fair Machine

We designed, developed and manufactured this special machine to demonstrate our expertise in special machine construction at trade fairs and other events.

Milled plastic parts are conveyed from a vibratory feeder and picked up by an individually automated robotic system. The robot's triple gripper picks up the parts and moves them linearly across a 3D measurer.

The good parts are fed to the indicated labelling system on a conveyor system and the bad parts are deposited separately. After labelling, the task is subject to an automated optical quality control by means of a camera system and the component is deposited “on the fly" by an axis system on another conveyor system.

Bad parts are discarded here, too. In order to create a cycle for demonstration purposes, all parts are returned to the separation system (vibratory feeder) at the end.

As previously mentioned, the esmo automation trade fair machine is just one of our many varied options when it comes to special machine construction.