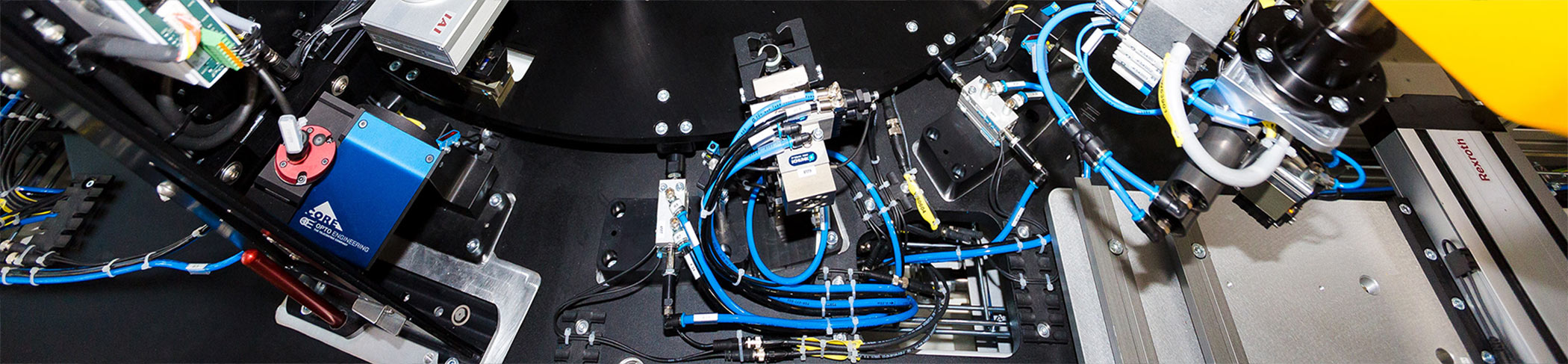

Unique automation solutions:

from standalone machines to interconnected machine systems

Optimise your production, packaging, and inspection processes in a sustainable, consistent manner. Tap on our automation solutions to guarantee your success, and exponentially increase your market presence.

Our solutions offer:

- Increased profitability

Reduce costs associated with operations, manufacturing, personnel deployment, and use of resources . - Improved productivity

Our advanced solutions help to increase production output and flexibility until you achieve 100% utilisation of your plant. - Ensuring quality standards

Manufacturing quality is increased and remains at a consistently high, verifiable level. You will also receive traceable data on machine, inspection, and process sequences, including required documentation. - Reduced manual labour

Spare your employees from repetitive and strenuous tasks and processes which that present health risks.

Contact us »

Or locate us at:

esmo automation

Plant II – Rosenheimer Str. 44

83064 Raubling

Tel.: +49 8031 23388450

Email: sales(at)esmo-ag.com

Customised

Machines for You

The manufacturing industry is becoming an increasingly digital function and many businesses are struggling to keep up with the latest demands is also increasing. Automation enables businesses to be in a better position to tackle challenges such as globalised markets, increased shortage of skilled labour, and rising production costs. In fact, implementing the right automation solutions can help companies successfully and sustainably optimise productivity, increase production times, and improve production quality.

And this is where our expertise lies. Working closely with you, our team will build the machine you need to achieve your business goals. We adopt an interdisciplinary approach and partner well-established firms to create a unique solution for you.

Discover more about our customisation solutions

Interconnected

Machinery Systems

How should manufacturers respond to the growing pressure of rising costs and shortage of skilled workers?

A strategic approach is to ensure that all processes are well coordinated, and all workflows are seamlessly intertwined. Redundant, inefficient processes cost time, money, and valuable energy that can be better used elsewhere.

This is especially relevant in the integration of individual machines, where they are linked to form a network of solutions, and also applicable to internal sales and administration workflows. esmo automation is your partner of choice — we provide personalised consultations to understand your business needs and integrate customised automated solutions into yourproduction processes to ensure yoursolution works efficiently and holistically.

From an idea to the series-produced machine:

Development, engineering, and manufacturing

As a full-service provider, we help develop automated solutions that are right for your operational requirements. We will work with our partners to develop, plan, design, and manufacture your solution based on your goals and ideas. Our team will support you at every stage of your automation journey, and we also provide ongoing support to update and upgrade your customised solution.

All of our design and development efforts are carried out in line with NASA’s Technology Readiness Level (TRL) measurement system.

Discover our development, engineering, and manufacturing capabilities

Machines constructed to plan:

Build to Print

Our team is also capable of building machines based on existing blueprints. We will follow your specifications and requirements (in terms of design, performance, quality, and quantity) to a tee.

Enjoy these benefits with your built-to-print machines:

- Continuous optimisation of production, assembly, inspection procedures, supply chains, and services;

- Cost transparency at every stage of production;

- high quality, increased reliability, and adherence to legal and safety regulations at every point of the decision-making and manufacturing process;

- rapid responsive to production surplus and peak workloads, saving associated downtime and costs;