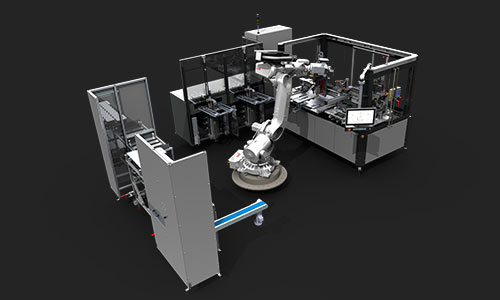

Machinery is used in almost every industry to manufacture complex products. In the case of mechanical plant engineering, this involves several interconnected special machines workingin perfect harmony. For safety reasons, these automated machines will be coordinated down to the smallest detail, handle challenging tasks that are too repetitive or complex to be carried out manually. Furthermore, these machine plants can perform the tasks accurately and reliably over longer periods of time.

Engaging the right partner is key to reaping these benefits. Our team will support you in the development, engineering, manufacturing, assembly, optimisation (e.g. increasing cycle times), and maintenance of your machine plant.

Enjoy these benefits with your esmo solution:

- streamlined workflows;

- increased productivity;

- improved product quality;

- reduced errors to a minimum;

- minimised downtimes;

- improved competitive advantage;

- optimised, cost-effective solutions;

- decreased reliance on manual labour.

Tap on our team of experts. From mechanical engineers and system integrators to certified assembly specialists, we will work closely with you to set up your solution.

As a team of automation experts, we have practical expertise, as well as extensive knowledge about the latest technology available. We guide our customers to develop and implement a sophisticated automation solution that is built for your needs and industry.

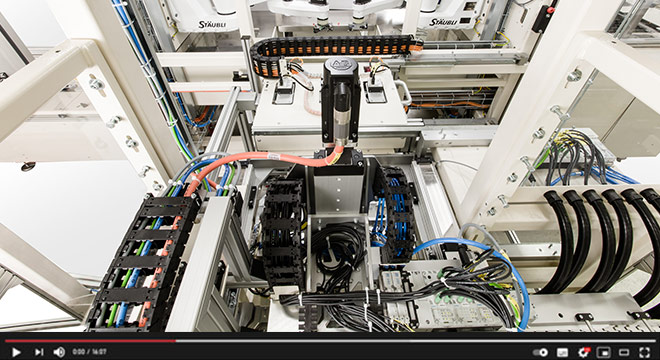

We will determine the workflow and engineer the machinery components according to your needs. Depending on your specifications, we will add a control and monitoring software and other automation technologies to your commissioned machine industrial system. Our team will take into account both safety-related and environmental factors, which includesoccupational safety and a careful approach to resources, energy, disposal, and recycling. After which, we will build and install an automated system that ensures maximum performance and effectiveness.

The engineers at esmo automation know what they’re doing,

and they’ll guide you to your goal,

with a few new ideas and shortcuts as a bonus.

We needed a plant that would automate various extremely complicated workflows one at a time.

This needed to be done as quickly as possible while maintaining a consistent level of quality,

and of course it also had to be affordable.

We ended up with a machine plant that exceeded our expectations.

It took a little longer than we thought, but that was a price worth paying for the excellent results.

S.V., Head of New Business Development, Industrial Engineering