| A | |

|---|

| AOI | automated optical inspection |

| ASM | asynchronous motor |

| AS/RS | automated storage and retrieval system |

| ATE | automatic test equipment, automated test equipment |

| C | |

|---|

| CAPA | corrective action, preventive action |

| CCM | change and configuration management |

| CCW, ccw | counterclockwise |

| CIP | continuous improvement process |

| CTC | cold temp cover |

| CTH | compact test head |

| CUH | contact unit holder |

| CW, cw | clockwise |

| D | |

|---|

| design freeze | The design freeze completes the design – the design has been examined and approved by the customer. Only then the purchasing process may commence.

In order to optimize/save project time, the design freeze may also take place in partial sections (for individual systems/plants/machines or assemblies).

The following features/criteria will be examined:

- system/plant/machine or assembly group functionality

- mountability/assembly

- operability/usability + ergonomics

- service accessibility + spare parts

- safety

The design freeze is an essential milestone, which will be elaborated and executed in a most detailed and conscientious manner by both esmo AG and their customers. Any design changes and follow-up costs occurring subsequent to the design freeze will be separately invoiced to the customer. |

| DFN | dual-flat no-leads |

| DIB, dib | device interface board |

| DMC | data matrix code |

| DMS | dead-man switch |

| DUT | device under test |

| E | |

|---|

| ECM | engineering change management |

| EIS | equipment identifying symbol |

| EMC | electromagnetic compatibility |

| EMO | emergency off |

| EOAT | end of arm tooling |

| EPO | emergency power off |

| ERP system | enterprise resource planning system |

| ESD | electrostatic discharge |

| F | |

|---|

| FAI | first article inspection |

| FAT | factory acceptance test ::: The FAT is a functional test of the system/plant/machine at esmo AG together with the customer. The objective is the early detection of critical faults in the system/plant/machine prior to delivery. The successfully passed FAT will be the prerequisite for the delivery release of the system/plant/machine, and the subsequent issuance of the third partial invoice.

The detailed functional scope of this test will be precisely defined in advance upon order placement – it will furthermore depend on the general testing and inspection possibilities of the system/plant/machine at esmo AG. |

| FEM | finite element method |

FIFO principle,

FIFO mode | first-in/first-out principle/mode |

| FMEA | failure mode and effects analysis |

| fs | femtosecond |

| FSE | field service engineer |

| G | |

|---|

| GPIB, GP-IB | General Purpose Interface Bus, General Purpose Instrumentation Bus |

| GTC | General Terms and Conditions |

| GUI | graphical user interface |

| H | |

|---|

| HMI | human/machine interface |

| HVM | high-volume manufacturing |

| I | |

|---|

| IC | integrated circuit |

| IPD | inner-pull-down |

| IP Code | international protection rating, ingress protection rating |

| L | |

|---|

| LCD, LC display | liquid crystal display |

| LED | light-emitting diode |

| LTH | large test head |

| M | |

|---|

| MA | modified atmosphere |

| MA packaging | modified atmosphere packaging |

| MLF | micro lead frame |

| N | |

|---|

| NCC | normally closed contact |

| NDA | non-disclosure agreement |

| ns | nanosecond |

| O | |

|---|

| OPD, opd | outer pull-down |

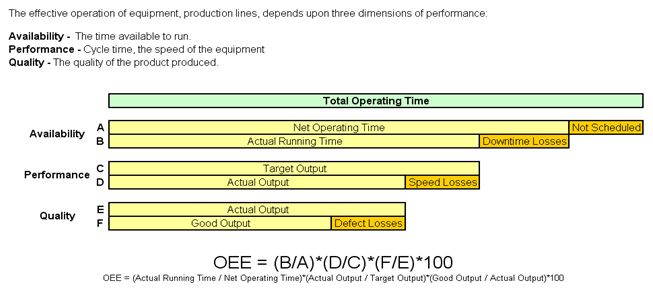

| OEE | overall equipment effectiveness ::: The OEE indicator – combining parameter availability, performance and quality – will constitute the basis for the acceptance of the system/plant/machine. The following chart depicts the calculation of the OEE:

Performance Efficiency

The term "performance efficiency" is defined as the ratio between the theoretical output and the quantity actually produced, including bad/reject parts. The theoretical output will be calculated by multiplying the declared or stated power of the system/plant/machine by its actual operating time.

Quality Factor

The term "quality factor" is defined as the ratio between the good products and all manufactured products

Note:

The system/plant/machine shall have satisfied all quality criteria of the products to be manufactured prior to the test. Any system/plant/machine, manufacturing inferior quality products, may not be tested.

|

| OJT | on the job training |

| OMO | one-man operation |

| OPC UA | Open Platform Communications Unified Architecture |

| OpMode, OPMODE | operation mode |

| OPD, opd | outer pull-down |

| OPO | one-person operation |

| OSAT | outsourced assembly and test |

| P | |

|---|

| PackML | packaging machine language |

| PCB | printed circuit board |

| PCQP | process control quality plan |

| PDA | production data acquisition |

| PDM system | product data management system |

| PDP, pdp | prober docking plate |

| PE | process engineer |

| PIB, pib | prober interface board |

| PLC | programmable logic controller |

| PPE | personal protective equipment |

| Q | |

|---|

| QFP | quad flat package |

| QFN | quad flat no leads package |

| QR code | quick response code |

| R | |

|---|

| RFID | radio frequency identification |

| RID | radio interference discrimination |

| RM(A) No | return material/merchandise authorization number |

| RPA | robotic process automation |

| Riemenspanner | belt tightener |

| S | |

|---|

| SAT | site acceptance test ::: The SAT is a functional test of the system/plant/machine at the customer site after assembly/installation and commissioning.

It should show and prove the proper installation and functionality of all safety devices.

Additionally, the system/plant/machine must have already fulfilled all defined customer safety check specifications and further requirements.

The control program is available and the system/plant/machine is ready for operation.

The system/plant/machine shall prove and meet all performance data and reliability requirements in a defined endurance test during SAT.

All operators and service staff are trained.

After passing the SAT, the system/plant/machine may be used for production.

Effective the date/time of the successfully passed SAT, the warranty period will commence,

and the area of responsibility for the system/plant/machine will be transferred to the customer.

The detailed functional scope of this test will be precisely defined in advance upon order placement.

After successfully passing the SAT, the system/plant/machine may be used for production –

all system/plant/machine-related documentation will be submitted/handed over to the customer:

- user/operating manuals

- technical data

- code words/passwords

|

| SCCR | short circuit current rating |

| SD card | secure digital memory card |

| SN | serial number |

| SOP | standard operating procedure |

| STH | small test head |

| T | |

|---|

| TH | test head |

| U | |

|---|

| UL marks, UL labels | Underwriters Laboratories marks/labels |

| W | |

|---|

| WAF | width across flats (wrench size) |