Our cross-sectoral experience across various industry verticals allows us to help engineer, develop, plan, and manufacture effective solutions and/or special machines that meet your automation needs.

To ensure you get the best parts and leading technologies, we have established long-term partnerships with major European manufacturers and suppliers. Tap on our network of partners to integrate digital technologies into your production facilities and throughout your operations.

Tell us about your ideas and needs!

Control and deploy your machines and other individual technologies with esmo CORE.

An automatic and modular construction platform, esmo CORE functions as the centre of your operations. Save operational time by accessing your machines’ control system, switchboard, remote maintenance module, and safety screen interface from one platform. And enjoy a seamless integration experience — esmo CORE is embedded with international standards such as PackML, OPC UA, and our partners’ standardised interfaces.

Equipped with a human machine interface (HMI), esmo CORE performs as a powerful, easy to use management tool that controls every function of your esmo machine. With esmo CORE, any engineer will be able to operate the machine independently.

esmo CORE also works to future-proof your machines. This means equipping your esmo machines with the necessary technologies needed to meet future environmental and digital requirements.

![[Translate to Englisch:] esmo CORE [Translate to Englisch:] esmo CORE](/automation/fileadmin/user_upload/images/technologien/esmo-CORE-Steuerungszentrale-automation-Sondermaschinen.jpg)

You have the power to decide how your parts should be made with feeding and separation technology.

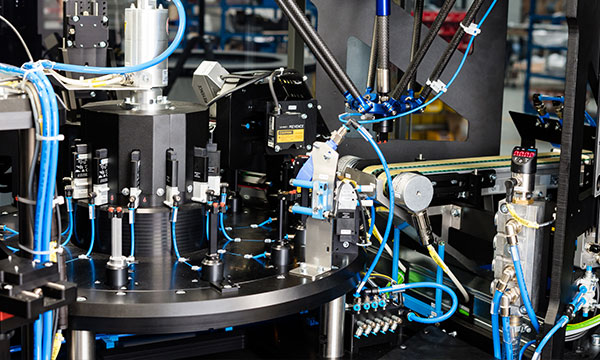

Your machine system can be customised to feature fast delta kinematics, tetrapods, 3-, 4-, 5- or 6-axis systems, conveyor belts, pick and place, and many other technologies for complex tasks.

You can make changes and adjustments to your machine through an easy-to-use touch interface, which is part of the human-machine interface (HMI). The esmo CORE serves as the central hub of your specialized machine, connecting all of its various technologies. Furthermore, the safety circuit can be linked to machines from other manufacturers using the OPC UA interface.

Entrust your fusion processes to us. Whether it’s assembling, screwing, pressing, riveting, gluing, or soldering, we have the right technology for you. We guarantee a high-quality end product with little to no downtime.

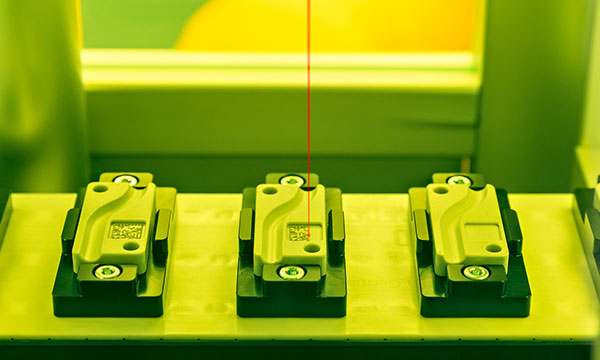

Specify how your products should be labelled and we’ll make sure that the labels remain traceable and recognisable. We use automated laser engraving with consecutive numbering or QR codes to guarantee traceability.

Our specialist companies offer the latest industrial image processing solutions and complex automatic optical inspection (AOI) systems. We also use mechanical and optical scanning solutions, which are an integral part of our non-destructive testing portfolio.

Design your machine to package the parts you produce. From stacking to individual labelling from batch size 1, there are endless packaging technology combinations that you choose from.

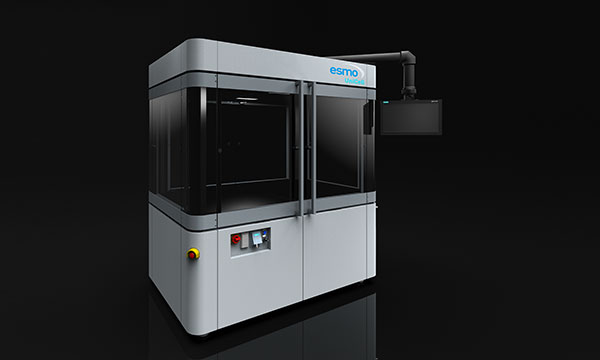

Tap on UniCell, our cross-industry compact automation housing solution that is best-suited for small- to medium-sized components with mid- to high-cycle rates. Configure your UniCell to perform specific production or testing tasks, and to integrate seamlessly into your automated production process.

The benefits you enjoy: