More speed. Higher quality. Less dependency.

A shortage of skilled workers, rising costs and increasing quality demands are putting manufacturing companies under pressure. Industrial automation addresses these challenges with stable processes, reproducible quality and measurable efficiency.

Automated systems relieve the burden on your team, safeguard your ability to deliver and make your production more flexible – even with small batch sizes or a high mix of variants.

Global competition, rising energy costs, a shortage of skilled workers and increasing quality requirements pose major challenges for manufacturing companies.

To remain competitive, it takes more than dedicated employees – it requires intelligent systems that carry out processes reliably, precisely and efficiently.

This is exactly where industrial automation comes into play: it relieves people of monotonous or hazardous tasks, increases productivity and ensures consistently high quality – around the clock.

In practice, many companies face similar obstacles in their production processes:

Whether in assembly, packaging or machine operation – finding qualified personnel is becoming increasingly difficult. Personnel planning is often a major uncertainty, particularly in shift operation or during seasonal fluctuations.

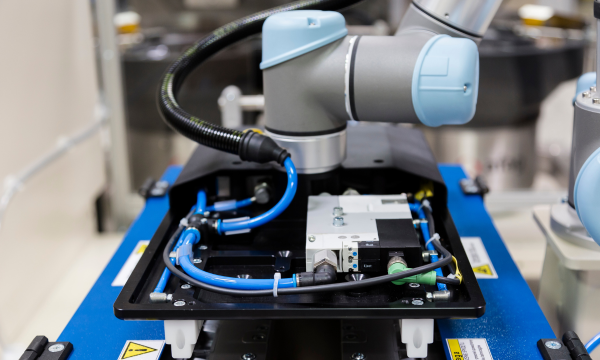

Automation solution: Handling units, robotic cells, pick-and-place systems or automated transport systems reliably take over tasks – independent of holiday periods or sickness-related absences.

Errors in manual processes can occur quickly – due to distraction, fatigue or unclear workflows. This results in scrap, rework and, in the worst case, customer complaints.

Automation solution: Machines operate precisely according to defined specifications – with continuous documentation and reproducible quality. In addition, vision systems can detect and correct errors directly during production.

The trend is towards greater product variety, customised solutions and smaller production runs. Traditional production lines are often not designed to handle this.

Automation solution: Flexible automation systems can be retooled in a very short time or automatically adapted – even down to batch size 1. This creates scope for greater customer focus and product diversity.

Energy, materials and labour – costs are rising across the board. At the same time, customers expect short lead times and competitive prices.

Automation solution: Through intelligent process optimisation, reduced downtime and predictive maintenance, industrial automation sustainably reduces operating costs – without compromising quality or delivery reliability.

What challenges are you currently facing?

We are confident we can find a cost-effective solution to address them.

Talk to us about the right automation solutions for your needs »

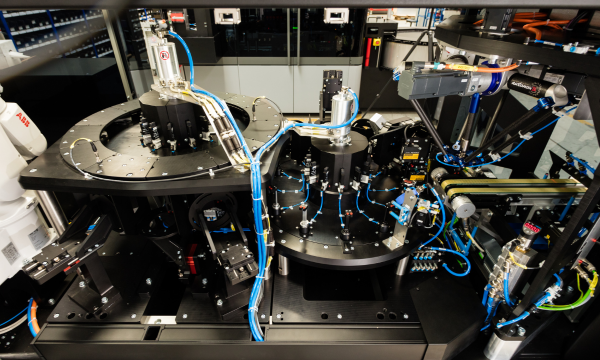

Special-purpose machinery

since 2001

Everything from a single source

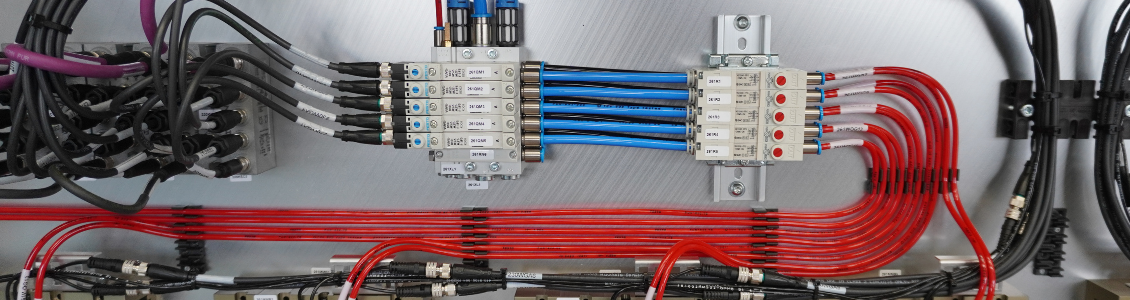

Mechanics, electrics, electronics and pneumatics – one single point of contact

In-house engineering

incl. software & control systems

Dedicated service team

for your production

Automated machines and robots operate reliably 24/7, without fatigue or loss of performance. This means higher output in less time – with consistent precision.

Once programmed, processes deliver reproducible results. Variations caused by shift work or human factors are eliminated, error rates decrease and customer complaints are reduced.

Instead of performing monotonous or physically demanding tasks, your team can focus on value-adding activities such as process optimisation, innovation and customer support.

Robots take over tasks that are hazardous or ergonomically challenging for people. This reduces accident risks and increases employee satisfaction.

Whether small batch sizes, increasing product variants or short-term market demands – modern automation technology can be adapted quickly, ensuring you remain capable of delivering at all times.

We will discuss which automation solution is right for you.

Many companies ask themselves: Is industrial automation worth it for us?

The answer is almost always: Yes – and faster than expected.

Typical effects include:

The result: payback is often achieved within just 18 to 36 months.

In addition, government funding programmes are available for digitalisation and automation, particularly for small and medium-sized enterprises.

Introducing industrial automation is not only a technological step, but above all a strategic one – with long-term benefits for the entire company.

Whether volatile markets, energy crises or supply chain disruptions – automated processes make you more independent and resilient. After all, your capacities are predictable and scalable.

Automation solutions provide the ideal foundation for further digitalisation steps – from the paperless shop floor to end-to-end data analysis. This creates transparency and a sound basis for decision-making.

Modern technology, clear processes and attractive tasks make your company more appealing to skilled professionals. Automation is transforming the world of work for the better.

Intelligent control systems enable targeted resource savings, for example through:

Invest in an automated future with more efficient, flexible and higher-quality production.

Tell us about your project and let us work together to develop the ideal solution for the automation potential in your manufacturing.

A practical example illustrates just how significant the impact of industrial automation can be:

| Criterion | Before: Manual | After: Automated |

|---|---|---|

| Production time | highly variable, dependent on shift and personnel | consistently fast, around the clock |

| Error rate | high, e.g. due to manual assembly | minimal, thanks to precise process control |

| Workforce deployment | high physical strain, monotonous tasks | value-adding activities such as monitoring and optimisation |

| Downtime | frequent due to operating errors or maintenance | predictable through condition monitoring and predictive maintenance |

| Data availability | hardly available or maintained manually | digital, analysable in real time |

Conclusion: Even for smaller sub-processes, automation delivers tangible benefits – both economically and organisationally.

Would you like to find out more?

High precision, error-free documentation and traceability are essential. Automation reduces risks and accelerates processes.

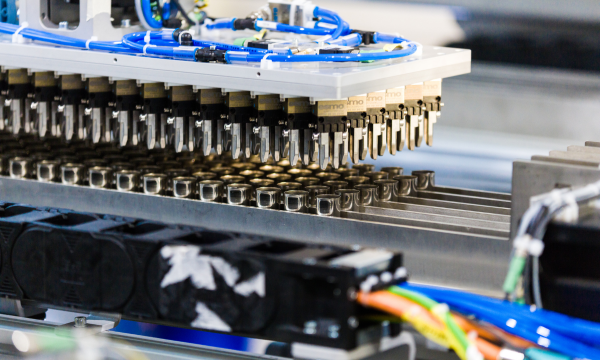

Automated production of printed circuit boards, cooling modules or components increases speed and reduces error rates.

From welding cells to final assembly – robots are used to safely and efficiently produce large volumes.

Automated packaging lines ensure hygiene, quality and consistent production.

Together with your team, we analyse your processes, identify bottlenecks and uncover automation potential. The goal: measures that deliver the highest ROI.

Based on the analysis, we develop a tailor-made automation concept – modular, scalable and manufacturer-independent.

From design and manufacturing through to commissioning: we support the entire process, carry out extensive testing and ensure seamless integration.

Our work does not end with project completion: we provide service, training and continuous optimisation to ensure your system always remains up to date.

Get started with a no-obligation analysis of your project.

A common misconception is that automation replaces people.

In reality, the opposite is true: people remain indispensable – only their role is changing.

In the future, employees will take on greater responsibility for:

This increases motivation and qualifications, reduces absenteeism and strengthens employer attractiveness.

Industrial automation is not a short-term trend, but the foundation for long-term business success.

It reduces costs, increases quality, makes processes more flexible and secures competitiveness – regardless of company size or industry.

With an experienced partner at your side, automation evolves from a purely technical project into a strategic success factor.

Not every company requires the same solution. The decisive factors are how varied your products are, the quantities you produce and how dynamically your market responds. In principle, there are four main types:

Which form of automation is best suited to your current challenge

can be clarified together in an initial discussion.

Ask us about the optimal automation solutions for your needs »

Industrial automation refers to the use of technical systems to make manual or semi-automated production processes more efficient and reliable. This includes, for example, assembly, inspection processes, handling or logistics.\n\nCompanies benefit not only from more stable workflows, but also from improved planning reliability – independent of shift work, sickness absence or fluctuating staffing levels. This creates new flexibility in manufacturing.

Traditional industrial automation ensures consistent processes within defined production chains. Industry 4.0 goes a step further: processes are interconnected, enriched with data and analysed in real time – often via ERP, MES or cloud systems.

Companies that have already automated their processes have the ideal foundation to further digitalise their production later on, without immediately launching a large-scale project. This keeps development scalable and investment-secure.

Industrial automation reduces error rates, ensures reproducible quality and enables more targeted use of personnel resources. At the same time, process speed increases – for example through shorter cycle times or fully automated inspection steps.

These effects are not limited to production itself, but also result in improved delivery times and higher customer satisfaction, often with a measurable impact on revenue and repeat business.

All recurring, standardisable or labour-intensive tasks are suitable for automation, such as material supply, component handling, screwing and joining processes, optical or electrical inspections, packaging or data traceability.

Especially in areas with high quality requirements or tight cycle times, industrial automation offers enormous potential for relieving staff and scaling output – without additional personnel costs.

Because customers today accept no excuses. Delivery reliability, quality and price must be right – for every order. Industrial automation makes exactly that possible: processes run reliably, even with fluctuating demand or unforeseen disruptions.

Those who invest early secure a long-term competitive advantage, as less improvisation is required and more can be planned with confidence.

Whether OPC UA, PROFINET, EtherCAT or Modbus – modern industrial automation relies on open interfaces to seamlessly connect machines, sensors, controllers and IT systems.

This ensures that your solution remains flexible and expandable, and can still be adapted to new requirements or IT structures years later without costly system changes.

More than ever. Thanks to scalable modules, flexible software solutions and compact designs, industrial automation is no longer reserved for large corporations.

Medium-sized companies in particular often benefit significantly: processes become more stable, capacities are used more effectively and dependency on personnel is reduced – without losing flexibility.

It usually starts with a thorough analysis: Which processes are worthwhile? Where are the bottlenecks? This is followed by modular integration – ideally without major modifications or long downtimes.

With the right partner, industrial automation can often be introduced during ongoing operations, ensuring your production remains capable of delivery even during implementation.

A typical project includes feasibility analysis, planning, design, software development, commissioning and training. The decisive factor is collaboration: the better your production requirements are understood, the more precisely the solution can be tailored.

Experienced providers such as esmo automation work transparently, in clearly defined steps, with the aim of enabling you to be productive from day one.

In most cases, ongoing support is provided by the system supplier or integrator – in other words, us – whether for updates, spare parts or system adaptations.

What matters is that service is genuinely available and that technical expertise is retained. This ensures your system not only remains operational, but can also be further developed when required.

Via secure remote access (e.g. VPN or industrial gateways), system statuses can be monitored live, faults analysed and software updates deployed.

This significantly reduces response times – and above all saves one thing: unplanned downtime and costly on-site interventions.

As connectivity increases, so does the potential attack surface. Modern automation solutions therefore rely on well-designed security concepts: network segmentation, access rights, encryption, regular updates and emergency plans have long been standard practice for us.

Those who plan ahead not only protect production data, but also safeguard operations against downtime, extortion or sabotage.

Robots are particularly flexible. They can be reprogrammed quickly and handle complex motion sequences. Classic automation, on the other hand, excels at very high cycle rates and clearly structured processes.

Depending on requirements, a combination of both technologies can often be the best solution: powerful, efficient and future-proof.

Reputable providers such as esmo automation support their systems for many years – with predictable service packages, spare parts logistics, updates and process optimisation. Many rely on dedicated contacts who have been familiar with your system from the outset.

This provides not only technical security, but also trust – especially when rapid responses are required in day-to-day operations.