Build-to-print (B2P) refers to the precise manufacture of products and assemblies based on customer-defined drawings and specifications.

Here you can find out how we deliver these projects: manufacturing, assembly, testing/documentation and on-time delivery – with fast ramp-up times and consistently accurate adherence to drawings.

Your benefits of contract manufacturing »

Discuss your build-to-print project with us – no obligation »

Full design control

Your engineering, our manufacturing expertise

Save time and costs

Manufacturing in Germany or China – depending on your budget and schedule

Everything from a single source

Mechanics, electrics, electronics and pneumatics – one dedicated point of contact

Scalable capacity

Flexibly scalable from one-off production to large-scale series

In a build-to-print project (also known as contract manufacturing), a product is manufactured exactly in accordance with predefined drawings, design data and bills of materials. No changes are made to the design or engineering.

The aim is to implement the customer’s plans with the highest possible level of accuracy. The process begins with a review and plausibility check of the documentation, followed by material procurement, component manufacturing, assembly and internal testing. Final acceptance is carried out by the customer, after which delivery takes place by lorry, sea freight or air freight.

The key advantage for companies: you retain full control over the design, while manufacturing is reliably outsourced to an experienced partner. Especially in machinery and plant engineering, this enables the efficient implementation of projects – whether individual machines or complex systems.

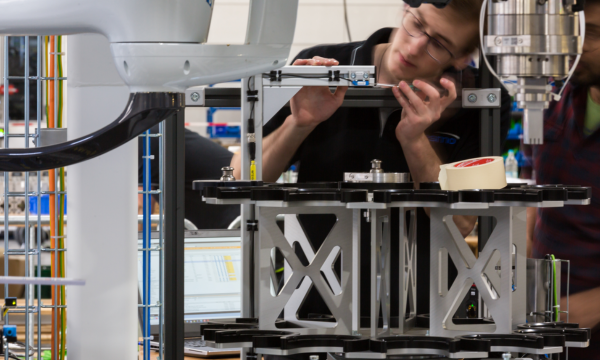

With the build-to-print approach, your design takes centre stage. You provide the drawings, bills of materials and specifications – we implement them precisely and efficiently during assembly.

For you, this means maximum control over the design, combined with the confidence that every manufacturing step is carried out by experienced specialists.

From the first component to the completed system, we ensure the highest level of accuracy and on-time delivery, supported by rigorous quality controls.

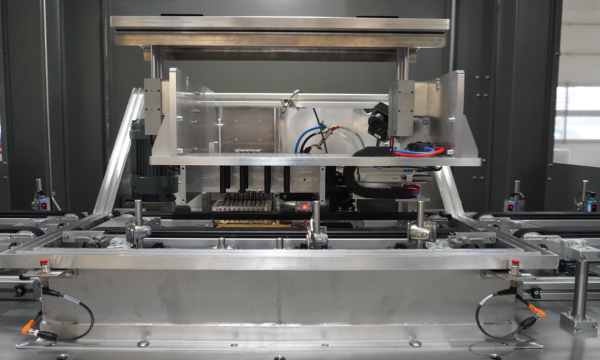

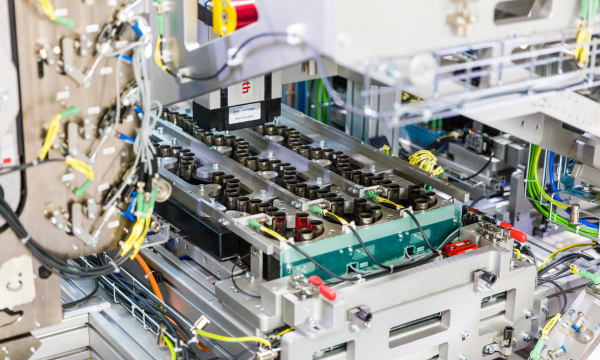

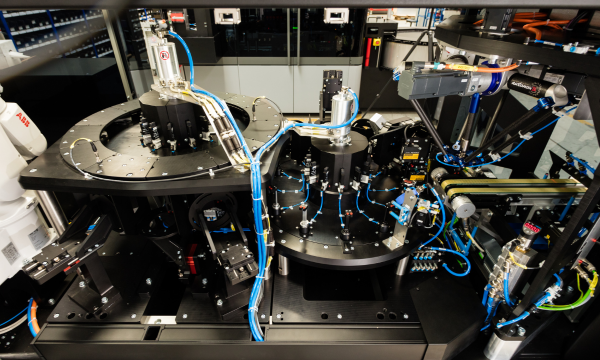

Our manufacturing teams work in state-of-the-art assembly halls, where your systems can even be tested under near-series conditions before delivery. This ensures that everything functions exactly as intended before it goes into operation at your site.

+ Manufacturing control: 100% inspection of all parts with documented measurement reports

+ Assembly & installation: Full compliance with all customer requirements and standards

+ Change management: Digital planning systems enabling fast and efficient adjustments

+ Process qualification: Proven capability ensured by process and methods experts

+ Certified procedures: EN and ISO standards applied across all relevant areas

Are you ready to take your production to the next level?

Let’s work together to identify the build-to-print solutions that best address your specific challenges.

With a high level of in-house production and the strength of a well-established corporate group, we offer a broad range of services and expertise – all from a single source.

CNC machining, surface finishing, assembly, wiring, software development and integration, as well as final acceptance, are all carried out under one roof. This reduces interfaces and gives you the assurance that every step is perfectly coordinated and seamlessly integrated.

Our capacity enables us to deliver projects of any scale – from one-off builds and small series to complex production lines worth several million euros. You benefit from flexible resources that adapt to your requirements and from processes designed for maximum efficiency.

Our production processes are designed to implement your specifications without deviation. Every part is 100% inspected and documented to ensure exact compliance with your drawing dimensions.

With a high level of in-house production and the strength of a strong corporate group, we carry out almost all manufacturing steps internally – from CNC machining and in-house control cabinet construction to assembly. This minimises interface risks and maximises on-time delivery.

Whether a prototype, a small series or a complex production line worth several million euros, we have the resources to meet your requirements with maximum flexibility.

+ Digital processes:

IT-supported workflows, from bills of materials to CAD data, for maximum transparency.

+ Day-to-day relief:

We take care of purchasing, schedule tracking, as well as project and supplier management on your behalf.

+ Access to expert knowledge:

You benefit from our extensive experience across all aspects of outsourcing.

+ Strong network:

Access to trusted partners for specialised tasks.

+ Reliable logistics:

Worldwide delivery by lorry, sea freight or air freight.

Precision is not a coincidence, but the result of clearly defined processes. Every component is 100% inspected and documented after manufacturing. Measurement reports and functional verification are standard for us, as is full compliance with all relevant standards and your specific requirements.

We also focus on speed and transparency in change management. Adjustments can be seamlessly integrated into the ongoing process via our system without jeopardising the schedule.

This allows us to respond quickly if requirements change during the project – while you retain full visibility at all times.

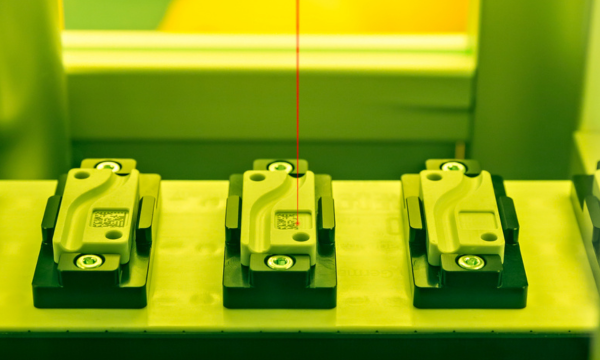

Leak, functional, voltage and optical tests

Forces, pressure, torque, temperatures, currents and more

Welding, riveting, clinching, pressing and more

Laser marking, label printing and engraving

Plasma and laser cleaning, depaneling

Leak, functional, voltage and optical tests

Your design data is a valuable asset, and we treat it with the highest level of care. NDAs, strict security protocols, trained employees and protected working environments ensure that your data is secure at all times.

From the initial contact through to final delivery, one principle applies: your information never leaves the protected environment of our company.

For us, this is not only a matter of responsibility, but also a key foundation for building long-term, trusted partnerships.

At the start of each project, we carefully review your documentation and align it with production requirements. Where appropriate, we suggest optimisations to achieve the best possible outcome for you. We then begin material procurement, supported by our own stockholding and an efficient supplier network.

During assembly, we precisely integrate all components – mechanical, pneumatic and electrical. We also handle software integration for all common control platforms. Following comprehensive testing and rigorous quality checks, final acceptance is carried out together with you. Only once everything meets your expectations do we package the system securely for transport and deliver it to your chosen location – worldwide by lorry, sea freight or air freight.

Review of your drawings, bills of materials and circuit diagrams – including a plausibility check and optional optimisation proposals.

Procurement of all purchased parts, in-house manufacturing of components, and strict quality control of every single part.

Mechanical, pneumatic and electrical assembly – including software integration across all common control platforms (e.g. B&R, Siemens, Beckhoff).

Functional tests, calibrations and end-of-line inspections under near-real operating conditions.

Joint acceptance, final documentation, and worldwide shipment by lorry, sea freight or air freight.

Receive your non-binding quotation easily by email »

– with a transparent schedule and clear costs.

Since 2001, companies from a wide range of industries have relied on our build-to-print expertise.

These include the semiconductor industry, special-purpose machinery, automotive and e-mobility, medical technology, as well as electrical and electronics manufacturing. Each of these sectors comes with specific requirements – and we understand them and implement them reliably.

Our international experience enables us to deliver even complex projects with short response times and a clear cost structure. For you, this means less coordination effort, greater planning certainty and faster delivery.

We see ourselves not merely as a contractor, but as an integral part of your value chain. Open communication, constructive feedback and a shared focus on long-term goals define the way we work together. Many partnerships begin with a single project and develop into long-term collaborations lasting many years.

This is also because we do more than just manufacture – we actively contribute to optimising your products and processes, whether through data adjustments, improvements in assembly, or new testing methods. We always think one step ahead.

We do not see ourselves simply as a supplier, but as an extended workbench and a strategic partner.

For you, this means:

direct access to our experts in design, engineering and quality assurance

open communication throughout the entire project

traceable supply chains

constructive feedback to optimise your products for future series

long-term collaboration for recurring projects

In many projects, the schedule is just as critical as quality. Our demand planning ensures that resources, processes and milestones are precisely aligned.

Regular status updates and transparent communication give you full visibility into the progress of your build-to-print project at all times.

When fast responses are required, our capacity and in-house manufacturing enable us to reschedule at short notice – without compromising on quality.

Getting started is straightforward: you share your requirements with us, we analyse your documentation and prepare a transparent quotation with a fixed timeline.

From there, we take over – from manufacturing through to final acceptance. You receive a solution that is precise, delivered on time and fully documented.

Whether a single machine or a complete production line, we deliver the quality you have designed and the efficiency you need to stay one step ahead of the competition.

Invest in a future with more efficient, more flexible and higher-quality production.

Tell us about your project and let’s work together to develop the ideal solution for potential bottlenecks in your manufacturing.

Request your non-binding quotation for build-to-print services »

Build-to-print is ideal when you already have complete design documentation and require reliable manufacturing. The approach is suitable for individual machines as well as complex systems or series production, where precision, on-time delivery and a reliable, financially stable partner are key.

The build-to-print approach can be used across a wide range of industries. Typical applications include special-purpose machinery, the semiconductor industry, automotive and e-mobility, medical technology, as well as electrical and electronics manufacturing. Wherever precise implementation of design specifications is required, build-to-print demonstrates its strengths.

Yes, particularly in the semiconductor industry, the highest levels of precision and on-time delivery are critical. Build-to-print enables the exact manufacture of systems that meet strict quality and process requirements, without deviation from the original specifications.

In special-purpose machinery, customer-specific concepts are often used. Build-to-print is particularly suitable when the design and drawings are already available and the focus is on precise, on-time implementation – with all the advantages of an experienced manufacturing partner.

Yes, the approach is not limited to simple parts or small assemblies. Complex assemblies incorporating mechanics, electrics, electronics and pneumatics can be integrated, assembled and tested – up to complete production lines.

A build-to-print or contract manufacturing project typically follows this process:

The duration depends on the size and complexity of the project. Smaller assemblies can be completed within a few weeks, while complete production lines may take several months. In all cases, we provide a transparent schedule with clearly defined milestones.

For us, project management means one central point of contact, transparent planning tools, regular status updates and a clearly defined timeline and cost framework. This ensures you always have full visibility.

After project completion, we support you with commissioning, service and spare parts supply. Depending on your requirements, maintenance and after-sales services can also be agreed to ensure long-term operational reliability.

Yes, customers are welcome to gain an on-site impression of our manufacturing capacities and processes. Upon request, we can arrange a visit to our assembly halls in Raubling or at our international locations

Minor ambiguities or missing details are clarified jointly. We carefully review your documentation and provide feedback to ensure that assembly and manufacturing can start smoothly. Where necessary, we propose optimisations – the final decision always remains with you.

We treat your design data with strict confidentiality. NDAs, secure IT systems, clearly defined access rights and trained employees ensure that your data is and remains fully protected.

Yes, of course – whether spare parts, additional modules or series production. Repeat orders are possible at any time. Thanks to documented processes and stored manufacturing data, we can produce identical parts or assemblies with precision even at a later date.